Air Feeds

Improve production with faster material flow speeds

and uniform accurate progressions.

Rapid-Air pioneered the first compact air feed with internal air circuitry, setting the technological and performance standards for the industry. The unique dual air valve system provides outstanding performance backed by reliability that has made Rapid-Air the recognized innovator and leader in air feed technology.

Superior versatility.

Rapid-Air feeds offer unmatched production flexibility. Their cost-effective operation often justifies permanent installation on die sets to minimize job setup time.

Easy installation and removal make Rapid-Air units the most versatile type of feeding equipment available. Two bolts are all it takes to install one. Stroke length and speed adjustments are positioned for easy access.

Feed a variety of material in any direction.

All kinds of coil stock plus paper, plastic, wire, fabrics, foil, tubing, extruded and preformed shapes can be fed at short and long progressions, and at different production speeds. Rapid-Air feeds are unequalled in handling both thin and delicate materials. Several actuation options allow our feeds to be used on standard production presses, electric presses, hydraulic presses, wire forming machines, multi-slide machines and special machines.

We offer a comprehensive range of standard models to feed flat stock up to 16” (406mm) wide, .150” (3.81mm) thick, and in lengths up to 20” (508mm). Pulling capacities of up to 250 pounds (114kg) are available on heavy duty models. Our smallest feed is capable of 260 cycles per minute at a 2” (50.8mm) progression and can cycle much faster at shorter progressions. Special models are available to meet unusual feeding requirements

| Model | Max Material Width | Max Stock Length*1 | Stock Thickness*2 | Speed Cycle/Min. (recom.)*3 | Pulling Capacity*4 |

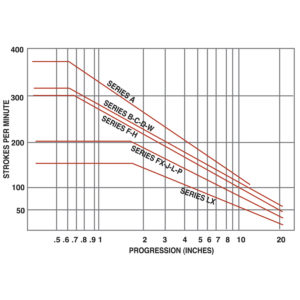

| A2 | 1 – 1/2” (38.1mm) | 2” (50mm) | .002” – .040” (.051-1.02mm) | 260 | 20 lbs (9.1kg) |

| A4 | 1 – 1/2” (38.1mm) | 4” (101mm) | .002” – .040” (.051-1.02mm) | 200 | 20 lbs (9.1kg) |

| A6 | 1 – 1/2” (38.1mm) | 6” (152mm) | .002” – .040” (.051-1.02mm) | 160 | 20 lbs (9.1kg) |

| B2 | 2 – 1/2” (63.5mm) | 2” (50mm) | .002” – .040” (.051-1.02mm) | 230 | 20 lbs (9.1kg) |

| B4 | 2 – 1/2” (63.5mm) | 4” (101mm) | .002” – .035” (.051-0.89mm) | 175 | 20 lbs (9.1kg) |

| C3 | 3” (76.2mm) | 3” (76mm) | .003” – .075” (.076-1.91mm) | 195 | 45 lbs (20.5kg) |

| C6 | 3” (76.2mm) | 6” (152mm) | .003” – .062” (.076-1.57mm) | 140 | 45 lbs (20.5kg) |

| C12 | 3” (76.2mm) | 12” (305mm) | .003” – .062” (.076-1.57mm) | 85 | 45 lbs (20.5kg) |

| D3 | 4” (101.6mm) | 3” (76mm) | .003” – .075” (.076-1.91mm) | 175 | 45 lbs (20.5kg) |

| D6 | 4” (101.6mm) | 6” (152mm) | .003” – .062” (.076-1.57mm) | 135 | 45 lbs (20.5kg) |

| W6 | 2” (50.8mm) | 6” (152mm) | .003” – .090” (.076-2.29mm) | 140 | 100 lbs (45.5kg) |

| W12 | 2” (50.8mm) | 12” (305mm) | .003” – .062” (.076-1.57mm) | 85 | 100 lbs (45.5kg) |

| W20 | 2” (50.8mm) | 20” (508mm) | .003” – .050” (.076-1.27mm) | 50 | 100 lbs (45.5kg) |

| F4 | 6” (152mm) | 4” (101mm) | .004” – .075” (.1-1.91mm) | 160 | 100 lbs (45.5kg) |

| F6 | 6” (152mm) | 6” (152mm) | .004” – .075” (.1-1.91mm) | 130 | 100 lbs (45.5kg) |

| F12 | 6” (152mm) | 12” (305mm) | .004” – .050” (.1-1.27mm) | 70 | 100 lbs (45.5kg) |

| F20 | 6” (152mm) | 20” (508mm) | .004” – .035” (.1-0.89mm) | 35 | 100 lbs (45.5kg) |

| H4 | 8” (203mm) | 4” (101mm) | .004” – .075” (.1-1.91mm) | 160 | 100 lbs (45.5kg) |

| H8 | 8” (203mm) | 8” (203mm) | .004” – .062” (.1-1.57mm) | 105 | 100 lbs (45.5kg) |

| FX6 | 6” (152mm) | 6” (152mm) | .005” – .150” (.13-3.81mm) | 105 | 145 lbs (66kg) |

| FX12 | 6” (152mm) | 12” (305mm) | .005” – .150” (.13-3.81mm) | 60 | 145 lbs (66kg) |

| L6 | 12” (305mm) | 6” (152mm) | .005” – .090” (.13-2.29mm) | 105 | 145 lbs (66kg) |

| L12 | 12” (305mm) | 12” (305mm) | .005” – .090” (.13-2.29mm) | 60 | 145 lbs (66kg) |

| P6 | 16” (406mm) | 6” (152mm) | .005” – .075” (.13-1.91mm) | 105 | 145 lbs (66kg) |

| P12 | 16” (406mm) | 12” (305mm) | .005” – .062” (.13-1.57mm) | 60 | 145 lbs (66kg) |

| LX12 | 12” (305mm) | 12” (305mm) | .005” – .125” (.13-3.18mm) | 50 | 250 lbs (114kg) |

- *1 Electric Actuating Valve is recommended for feeds that have stroke length over 8” (203mm). Add “E” to model number.

- *2 Thinner materials and/or long strokes with thin materials possible by using anti-buckling guides.

Maximum thickness capacity increases by same percentage as stock width decreases (up to max. of 150%). - *3 Approximate at maximum stroke length. Heavy stock requires slower speeds.

- *4 At 100 psi (6.9 bar). (Includes allowance for normal friction of moving parts).

Add “W” to Model A or B for replaceable wear plates (standard on all other models).

Add “P” to model no. for feed with control port only. Add “S” to model no. for feed with end-of-stroke sensors.

Feeds should always draw material from a free loop, supplied by a powered reel or powered straightener.

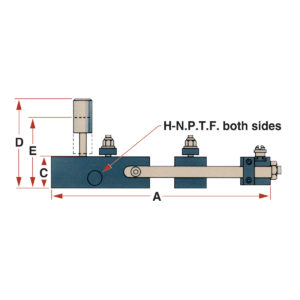

| Model | A | B | C | D | E | F | G | H | J | K | L |

| A2 | 8.69″ (220mm) | 3.22″ (81mm) | 1.24″ (31mm) | 3.50″ (88mm) | 2.69″ (68mm) | 0.38″ (9mm) | 2.62″ (66mm) | 1/8 (3mm) | .33 (8mm) | 1.31 (33mm) | .50 (12mm) |

| A4 | 12.69″ (322mm) | 3.22″ (81mm) | 1.24″ (31mm) | 3.50″ (88mm) | 2.69″ (68mm) | 0.38″ (9mm) | 2.62″ (66mm) | 1/8 (3mm) | .33 (8mm) | 1.31 (33mm) | .50 (12mm) |

| A6 | 16.69″ (423mm) | 3.22″ (81mm) | 1.24″ (31mm) | 3.50″ (88mm) | 2.69″ (68mm) | 0.38″ (9mm) | 2.62″ (66mm) | 1/8 (3mm) | .33 (8mm) | 1.31 (33mm) | .50 (12mm) |

| B2 | 8.69″ (220mm) | 4.22″ (107mm) | 1.24″ (31mm) | 3.50″ (88mm) | 2.69″ (68mm) | 0.38″ (9mm) | 3.62″ (91mm) | 1/8 (3mm) | .33 (8mm) | 1.31 (33mm) | .50 (12mm) |

| B4 | 12.69″ (322mm) | 4.22″ (107mm) | 1.24″ (31mm) | 3.50″ (88mm) | 2.69″ (68mm) | 0.38″ (9mm) | 3.62″ (91mm) | 1/8 (3mm) | .33 (8mm) | 1.31 (33mm) | .50 (12mm) |

| C3 | 12.25″ (311mm) | 5.50″ (139mm) | 1.73″ (43mm) | 5.50″ (139mm) | 4.12″ (104mm) | 0.50″ (12mm) | 4.50″ (114mm) | 1/4 (6mm) | .39 (9mm) | 1.53 (38mm) | .62 (15mm) |

| C6 | 18.25″ (463mm) | 5.50″ (139mm) | 1.73″ (43mm) | 5.50″ (139mm) | 4.12″ (104mm) | 0.50″ (12mm) | 4.50″ (114mm) | 1/4 (6mm) | .39 (9mm) | 1.53 (38mm) | .62 (15mm) |

| C12 | 30.25″ (768mm) | 5.50″ (139mm) | 1.73″ (43mm) | 5.50″ (139mm) | 4.12″ (104mm) | 0.50″ (12mm) | 4.50″ (114mm) | 1/4 (6mm) | .39 (9mm) | 1.53 (38mm) | .62 (15mm) |

| D3 | 12.25″ (311mm) | 6.50″ (165mm) | 1.73″ (43mm) | 5.50″ (139mm) | 4.12″ (104mm) | 0.50″ (12mm) | 5.50″ (139mm) | 1/4 (6mm) | .39 (9mm) | 1.53 (38mm) | .62 (15mm) |

| D6 | 18.25″ (463mm) | 6.50″ (165mm) | 1.73″ (43mm) | 5.50″ (139mm) | 4.12″ (104mm) | 0.50″ (12mm) | 5.50″ (139mm) | 1/4 (6mm) | .39 (9mm) | 1.53 (38mm) | .62 (15mm) |

| W6 | 19.94″ (506mm) | 5.00″ (127mm) | 1.98″ (50mm) | 5.75″ (146mm) | 4.31″ (109mm) | 0.69″ (17mm) | 4.25″ (107mm) | 1/4 (6mm) | .53 (13mm) | 2.62 (66mm) | .56 (14mm) |

| W12 | 31.94″ (811mm) | 5.00″ (127mm) | 1.98″ (50mm) | 5.75″ (146mm) | 4.31″ (109mm) | 0.69″ (17mm) | 4.25″ (107mm) | 1/4 (6mm) | .53 (13mm) | 2.62 (66mm) | .56 (14mm) |

| W20 | 47.94″ (1217mm) | 5.00″ (127mm) | 1.98″ (50mm) | 5.75″ (146mm) | 4.31″ (109mm) | 0.69″ (17mm) | 4.25″ (107mm) | 1/4 (6mm) | .53 (13mm) | 2.62 (66mm) | .56 (14mm) |

| F4 | 15.62″ (396mm) | 9.25″ (234mm) | 1.98″ (50mm) | 5.75″ (146mm) | 4.31″ (109mm) | 0.62″ (15mm) | 7.50″ (190mm) | 1/4 (6mm) | .66 (16mm) | 2.16 (54mm) | .56 (14mm) |

| F6 | 19.62″ (498mm) | 9.25″ (234mm) | 1.98″ (50mm) | 5.75″ (146mm) | 4.31″ (109mm) | 0.62″ (15mm) | 7.50″ (190mm) | 1/4 (6mm) | .66 (16mm) | 2.16 (54mm) | .56 (14mm) |

| F12 | 31.62″ (803mm) | 9.25″ (234mm) | 1.98″ (50mm) | 5.75″ (146mm) | 4.31″ (109mm) | 0.62″ (15mm) | 7.50″ (190mm) | 1/4 (6mm) | .66 (16mm) | 2.16 (54mm) | .56 (14mm) |

| F20 | 47.62″ (1209mm) | 9.25″ (234mm) | 1.98″ (50mm) | 5.75″ (146mm) | 4.31″ (109mm) | 0.62″ (15mm) | 7.50″ (190mm) | 1/4 (6mm) | .66 (16mm) | 2.16 (54mm) | .56 (14mm) |

| H4 | 15.62″ (396mm) | 11.25″ (285mm) | 1.98″ (50mm) | 5.75″ (146mm) | 4.31″ (109mm) | 0.62″ (15mm) | 9.50″ (241mm) | 1/4 (6mm) | .66 (16mm) | 2.16 (54mm) | .56 (14mm) |

| H8 | 23.62″ (599mm) | 11.25″ (285mm) | 1.98″ (50mm) | 5.75″ (146mm) | 4.31″ (109mm) | 0.62″ (15mm) | 9.50″ (241mm) | 1/4 (6mm) | .66 (16mm) | 2.16 (54mm) | .56 (14mm) |

| FX6 | 23.38″ (593mm) | 10.00″ (254mm) | 2.48″ (62mm) | 7.38″ (187mm) | 5.38″ (136mm) | 0.62″ (15mm) | 8.00″ (203mm) | 1/2 (12mm) | .66 (16mm) | 3.84 (97mm) | .88 (22mm) |

| FX12 | 35.38″ (898mm) | 10.00″ (254mm) | 2.48″ (62mm) | 7.38″ (187mm) | 5.38″ (136mm) | 0.62″ (15mm) | 8.00″ (203mm) | 1/2 (12mm) | .66 (16mm) | 3.84 (97mm) | .88 (22mm) |

| L6 | 23.38″ (593mm) | 16.50″ (419mm) | 2.48″ (62mm) | 7.38″ (187mm) | 5.38″ (136mm) | 1.00″ (25mm) | 14.00″ (355mm) | 1/2 (12mm) | .66 (16mm) | 3.84 (97mm) | 1.53 (38mm) |

| L12 | 35.38″ (898mm) | 16.50″ (419mm) | 2.48″ (62mm) | 7.38″ (187mm) | 5.38″ (136mm) | 1.00″ (25mm) | 14.00″ (355mm) | 1/2 (12mm) | .66 (16mm) | 3.84 (97mm) | 1.53 (38mm) |

| P6 | 23.39″ (594mm) | 20.48″ (520mm) | 2.48″ (62mm) | 7.38″ (187mm) | 5.38″ (136mm) | 1.00″ (25mm) | 18.00″ (457mm) | 1/2 (12mm) | .66 (16mm) | 3.84 (97mm) | 1.53 (38mm) |

| P12 | 35.39″ (898mm) | 20.48″ (520mm) | 2.48″ (62mm) | 7.38″ (187mm) | 5.38″ (136mm) | 1.00″ (25mm) | 18.00″ (457mm) | 1/2 (12mm) | .66 (16mm) | 3.84 (97mm) | 1.53 (38mm) |

| LX12 | 35.39″ (898mm) | 18.00″ (457mm) | 2.98″ (75mm) | 7.88″ (200mm) | 6.00″ (152mm) | 1.00″ (25mm) | 14.00″ (355mm) | 1/2 (12mm) | .66 (16mm) | 3.59 (91mm) | 2.24 (56mm) |