Accessories & Options

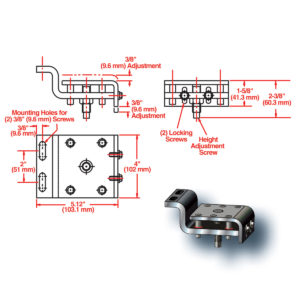

PILOT RELEASE STOCK CLAMPS

The spring-loaded stock clamp, optional with all Rapid-Air feeds, is recommended for most applications. For unusual requirements, the pilot release stock clamp is available. An electric signal actuates the pilot release clamp so that it lifts completely to allow for free movement of stock to position material when pilots are used. Solenoid valve not included. Order separately from Rapid-Air.

MODEL TC3 & TW6 TRANSPORTERS

- Conveys scrap or parts quickly and economically.

- Crisp, sharp tray action shuffles parts off faster.

- Eliminates costly conveyors and belt replacement.

- Compact low profile for better clearance.

- Easily mounted. Perfect for tight areas.

- Low cost, long life wear parts.

- Low maintenance.

- Precision designed and built with the same rugged reliability as our Rapid-Air feeds.

- Air pressure operating range 20 to 80 psi (1.4 to 5.5 bar). Easy access speed adjustment screw for fine tuning.

- Easily moves 10 lbs. (4.5kg) at 40 psi (2.8 bar) air pressure.

- Accepts higher pressures for heavier loads.

- Special shuttle trays, tray surfaces and accessories available.

- Convey high temperature parts.

| Model | Load Capacity | Recom. Speed SPM (adj.) | Feed Rate (per min.) | Air Pressure Range |

| TC3 | 10 lbs (4.5kg) | 175 | 300” (7.6m) | 20-80 psi (1.4 – 5.5 bar) |

| TW6 | 20 lbs (9.0kg) | 175 | 350” (8.9m) | 20-80 psi (1.4 – 5.5 bar) |

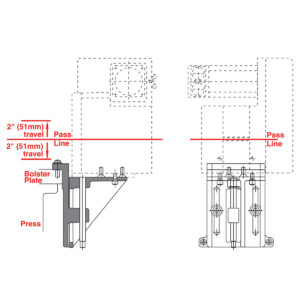

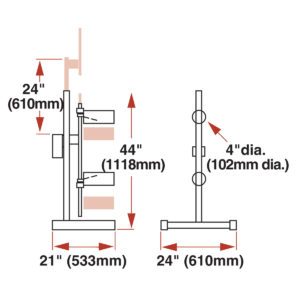

ENTRANCE CASCADE ROLLS

Fully adjustable entrance cascade rolls are available for all models.

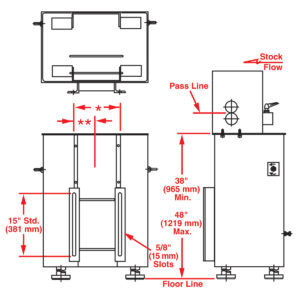

MODEL RS3

Optional optical non-contact loop control

Automatically adjusts the operating speed of a powered reel to maintain a free material loop and to match material flow to a required line speed. No moving parts, no stock contact, no loop sensing arm, mechanical linkage or other hardware. Works with equal precision for both conductive and non-conductive materials. The optical distance sensor locates the material position anywhere in the sensing range. Signals are transmitted to an integral microprocessor which programs the speed of the coil reel. A free loop, even at high speeds, can be kept under precise control without erratic stop and start. Special stock types and configurations can be processed without damage – regardless of coil coating finishes, density or capacity.

MODEL RS3

Optional optical non-contact loop control

Automatically adjusts the operating speed of a powered reel to maintain a free material loop and to match material flow to a required line speed. No moving parts, no stock contact, no loop sensing arm, mechanical linkage or other hardware. Works with equal precision for both conductive and non-conductive materials. The optical distance sensor locates the material position anywhere in the sensing range. Signals are transmitted to an integral microprocessor which programs the speed of the coil reel. A free loop, even at high speeds, can be kept under precise control without erratic stop and start. Special stock types and configurations can be processed without damage – regardless of coil coating finishes, density or capacity.

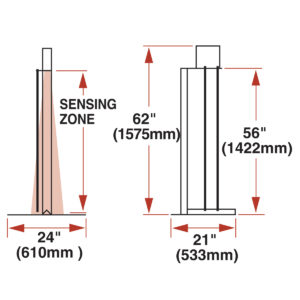

MODEL RTB

Optional electronic hi-lo touch system loop control

The Rapid-Touch system works without use of a material sensing arm by sensing the upper and lower position of conductive material. For use with non-conductive material, an adjustable probe is furnished on the inside of the large diameter, flexible sensors. As the material ranges between the sensors, a solid state controller automatically sets the most uniform line speed for continuous operation and changes this speed to match variable requirements. Power requirements and interfacing are satisfied when the plug connection is made with the Rapid-Air reel. Sensor height is adjustable three ways to accommodate varying material loop positions.

MODEL RTB

Optional electronic hi-lo touch system loop control

The Rapid-Touch system works without use of a material sensing arm by sensing the upper and lower position of conductive material. For use with non-conductive material, an adjustable probe is furnished on the inside of the large diameter, flexible sensors. As the material ranges between the sensors, a solid state controller automatically sets the most uniform line speed for continuous operation and changes this speed to match variable requirements. Power requirements and interfacing are satisfied when the plug connection is made with the Rapid-Air reel. Sensor height is adjustable three ways to accommodate varying material loop positions.

| Model | Description | Used With |

| RS1 | Rapid-Sense Ultrasonic Loop Control | Reels, Straighteners & Power Rolls |

| RTB | Rapid-Touch Loop Control with Base Mounting | Reels, Straighteners & Power Rolls |

OPTIONAL LLRIC / LLRIM

Remote mount single actuating arms.

The modular design of our Rapid-Air proportional loop arm allows it to be remote mounted. This offers operators a high degree of loop flexibility in unique payout and rewind applications.

OPTIONAL LLRIC / LLRIM

Remote mount single actuating arms.

The modular design of our Rapid-Air proportional loop arm allows it to be remote mounted. This offers operators a high degree of loop flexibility in unique payout and rewind applications.

EXTERNAL LOOP CONTROL PORT

Included with all powered reels and straighteners.

Our standard loop control for Rapid-Air power products is a pushbutton unit with digital display. This very flexible proportional control allows fine setting or speed, loop angle and loop height. A remote or external loop sensor may be plugged directly into this control as an alternate loop control.

EXTERNAL LOOP CONTROL PORT

Included with all powered reels and straighteners.

Our standard loop control for Rapid-Air power products is a pushbutton unit with digital display. This very flexible proportional control allows fine setting or speed, loop angle and loop height. A remote or external loop sensor may be plugged directly into this control as an alternate loop control.