Custom Solutions

Your stamping operation is unique.

Rapid-Air realizes your manufacturing is unique. We can modify a line or an individual unit to suit your special requirements. Our emphasis has always been on engineering superior innovative solutions. All of our products are:

- Engineered and manufactured in the U.S.A. in our own factories.

- Many modifications and accessories are available.

- Application engineers are on staff, so products can be easily and quickly modified to your specific needs.

- We offer extensive in-house programming capabilities for your feeding and coil handling control needs.

We listen, engineer and build:

- FEEDS – special programs, profiles, materials, guides.

- REELS – combinations, special H.T., shorts,special features.

- STRAIGHTENERS – coil handling, strip, piece,integrated, special reliefs.

- CUTTERS – prox. S.W., press foot, blades,special materials.

- LOOP CONTROL – remote, variety of models,unique space-saving designs.

Custom Programming

Whatever your special manufacturing requirements may entail, Rapid-Air has the experienced engineers on staff to provide the custom programming solutions you need for your unique stamping operations. Special programs and displays, gag, metric, cut-to-length, multiple languages, special job storage requirements and many other programming capabilities are all routinely available and satisfied in-house for even the most unusual requirements. Rapid-Air is well known for developing intelligent control solutions, such as those which accompany our new servo line. One example, our new “Smart” MiniServo, which offers the control features of larger, more expensive servo feeds, is revolutionizing productivity for many stamping operations. If increased productivity, flexibility and efficiencies are your goal, put our programming engineers to work for you.

Mechanical Modifications

Rapid-Air can make both control and many mechanical system modifications to our standard equipment models to suit your individual production process. Often relatively inexpensive modifications can bring effective solutions to difficult feeding problems. Air or mechanical pilot releases, air regulated feed roll pressure, anti-backup rolls, adjustable cascade rolls, adjustable mounting brackets and stands, special feed roll surfaces, special roll reliefs, roll grooves and profiles, antibuckling stock guides, actuating valve controls, belt feed attachments and more are all available.

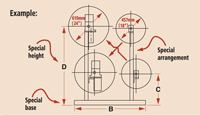

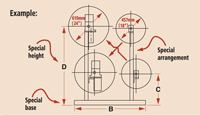

Modified Reel Example

For a product such as reels, any number of multi-head setups can be put in place to accommodate your manufacturing needs. One reel setup can be in full operation while the other is standing by, ready to make a smooth and quick changeover. Less downtime means added production efficiency. Inserting interleaf material to protect delicate, plated or intricately shaped materials that could snag or tangle is a simple procedure. Multi-head reels also allow you to put tension on the stock for a tighter, more compact wrap. Shown is just one example of how Rapid-Air can modify a special reel arrangement, special height and special base to suit your needs.

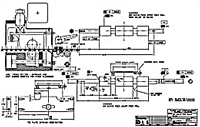

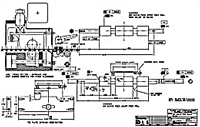

Modified Cut-To-Length System

The cut-to-length system pictured here employs a cutter and air/servo feed. Machine models utilizing air feeds can include modified stock and feed clamps for unusual material shapes or anti-buckling guides or tubes for very thin material. Combining a servo feed with one of our reciprocating blade cutters offers the advantages of high-speed, precision material movement and quick job changeover which is particularly useful for long feed lengths. This example shows a servo feed and a cutter mounted on a machine table base.